Vietnam’s pig farming industry, from household scale to large-scale industrial farms, plays a crucial role in the country’s food security and economy. However, this rapid development brings with it a “serious problem”: environmental pollution from wastewater and solid waste.

Characterized by extremely high organic pollution, concentrations of Ammonia, Nitrogen, and Phosphorus exceeding thresholds, a large volume of solid waste from manure, along with unpleasant odors and the risk of disease outbreaks, pig farm wastewater, if not treated thoroughly, will cause severe pollution of water, land, and air, and directly affect public health. Is your farm facing pressure to comply with QCVN 62-MT:2025/BTNMT, are the operating costs of your existing treatment system too high, or are you simply looking for a “greener,” more efficient solution?

I. Characteristics of pig farming in Vietnam.

Vietnamese livestock farming in general, and pig farming in particular, began to restructure its crop and livestock system since we joined regional markets (AFTA) and the World Trade Organization (WTO). Since then, alongside small-scale household farming, concentrated industrial farming in the form of farms and private enterprises has formed and grown strongly.

1.1. Forms of pig farming in Vietnam

Household scale (or traditional farming):

- About 4 million households with a scale of 10-100 pigs in a small area, often combined with fish farming or cultivation

- Pig farming waste is used for fish feed or as manure for crops

Farm scale (industrial farming):

- About 5,000 farms with a scale of over 100 pigs in a large area

- Farms are divided into sow farms (with piglets) and market hog farms. Some farms mix sows and market hogs.

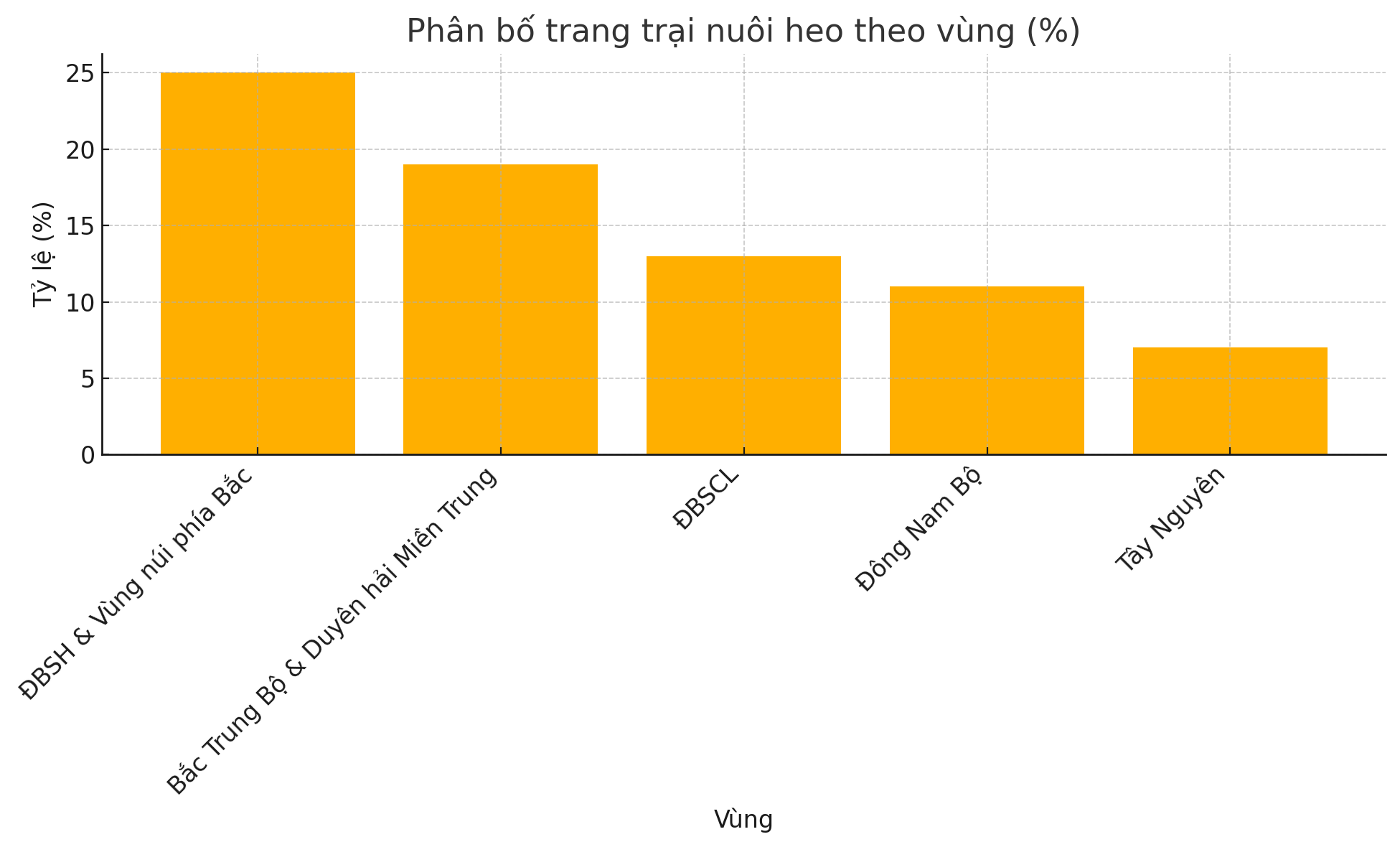

1.2. Distribution of pig farms in Vietnam

Pig farms are mainly distributed in the Red River Delta, Central Highlands, Northern mountainous region (25%); North Central Coast and South Central Coast (19%); Mekong River Delta (13%); Southeast and Central Highlands (11% and 7%)

II. Composition of pig farm wastewater.

Livestock wastewater in general and pig farm wastewater in particular is a mixture of animal excretions and water used for cleaning pens. Although it does not contain toxic substances like wastewater from other industries (acids, alkalis, heavy metals…), it contains many bacteria, larvae, and helminths, posing numerous risks to human health.

According to survey statistics from pig farms with over 1000 pigs, on average, one pig consumes 15-60 liters of water per day. The average wastewater volume is 25 liters/pig. Additionally, the amount of manure from market hogs is estimated at 2.7 kg/hog/day , which is not separated but discharged along with pen cleaning water into the biogas digester.

Currently, most pig farms do not collect and treat solid waste separately. Pig manure, leftover feed, urine, and cleaning water are all treated in a biogas digester. This results in very high wastewater pollution concentrations, with COD ~6000mg/l and Ammonia ~1200mg/l.

Analysis results from the Hanoi Institute of Environmental Technology in 2012 at several pig farms in the Northern region show that pig farm wastewater has COD, Nitrogen, Ammonia, and SS concentrations many times higher than the permitted wastewater standards.

Wastewater composition at some pig farms in the northern region

|

|

pH

|

T0C

|

COD (mg/l) |

T-N (mg/l) |

N-NH4+ (mg/l) |

T-P (mg/l) |

SS (mg/l) |

|

Vinh Phuc |

7.32 |

29 |

4590 |

967.3 |

870 |

295 |

9520 |

|

Hung Yen |

7.87 |

30.5 |

3584 |

202 |

158 |

54.9 |

1880 |

|

Thai Binh |

7.3 |

30 |

2575 |

425 |

425 |

102 |

800 |

|

Hanoi |

7.5 |

32 |

7219 |

247 |

237 |

120 |

3200 |

(Hanoi Institute of Environmental Technology)

However, the characteristics of pig farm wastewater vary significantly depending on the farming method and facility management (such as whether solid waste and wastewater are separated), and the specific conditions of each province. These conditions have a significant impact on the scale of treatment and make maintaining the treatment system difficult and costly.

III. Livestock Wastewater Treatment Technology

3.1 Disadvantages of current treatment technologies

Currently, many livestock wastewater treatment technologies are applied in Vietnam, including composting, biogas technology, biological ponds, etc., where biogas helps control odors, reduce pollutant content in wastewater, and can be used as fuel.

However, practical implementation shows that these technologies still have serious shortcomings, leading to high costs and failing to ensure long-term effectiveness.

1

Clogging & Costly Operation

- The system is constantly overloaded, with pipes frequently clogged by waste and scale buildup.

- Requires the use of many nutrient-supplying chemicals and additional expensive investments like flaring towers or gas recovery systems for power generation.

2

Air Pollution

- Biogas ponds and anaerobic tanks generate large amounts of greenhouse gases (Methane) and foul odors, directly affecting the living environment and surrounding areas.

- To comply with regulations, the project owner needs to invest further in an off-gas treatment system

3

Fails to Meet New Standards

Although they can treat organic pollution, old systems struggle to completely remove Nitrogen and Phosphorus, failing to meet the discharge standards of QCVN 62-MT:2025/BTNMT because high pollutant concentrations make it difficult to control the microbial treatment process in practice

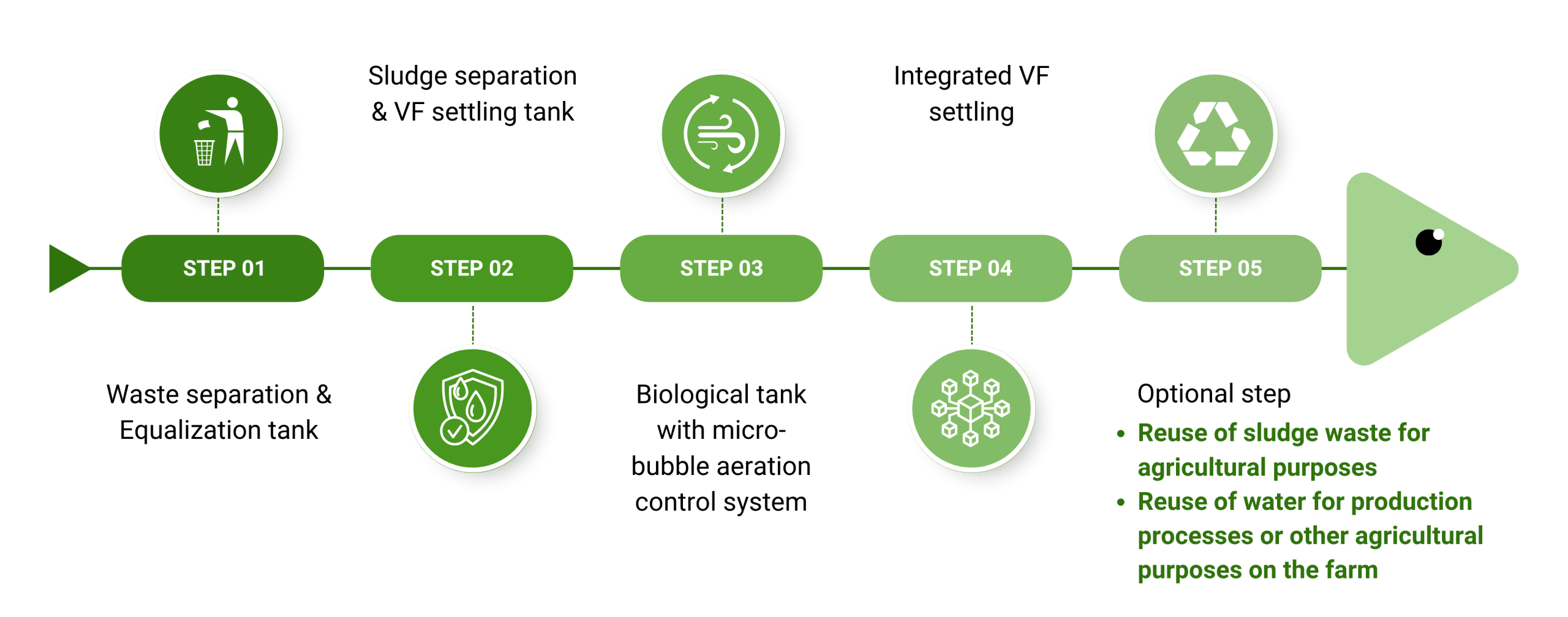

3.2 NGO’s New Pig Farm Wastewater Treatment Technology

Space-Saving – No Biogas Ponds Needed – Effluent Meets Grade A Standard

NGO’s pig farm wastewater treatment technology applies an advanced microbial system, which optimizes construction area and can bypass the traditional biogas treatment step. Our secret is to minimize the time for separating manure from wastewater, thereby increasing microbial activity efficiency and reducing operating costs.

The pig farm wastewater treatment process using NGO technology:

As a result, the treated wastewater meets the Grade A standard according to QCVN 62-MT:2025/BTNMT

3.3. Outstanding Advantages of NGO Technology

- Saves operating costs: by reducing sludge generated from the treatment process and minimizing chemical use for microbial reactions

- Maximizes manure & sludge utilization: The by-product after treatment is fertilizer for crops, without generating polluting CH4 gas as it does not use biogas ponds and anaerobic tanks

- Simplified technological process: The technology process is maximally simplified, helping to reduce construction area and simplify operational procedures.

Some construction photos of a pig farm wastewater treatment project

IV. Frequently Asked Questions

Pig farm wastewater is rich in organic matter (COD, BOD), Ammonia (N-NH4+), Total Nitrogen (T-N), Total Phosphorus (T-P), suspended solids (SS), and pathogenic microorganisms. It is one of the most highly polluted types of wastewater.

The national technical regulation for livestock wastewater is QCVN 62-MT:2016/BTNMT. Farm owners must comply with the pollution limits specified in this regulation.

A Biogas digester is only a preliminary treatment step, helping to reduce some organic matter and recover gas. The effluent from the biogas digester still has very high concentrations of Ammonia, Nitrogen, and Phosphorus and cannot meet QCVN 62-MT:2016/BTNMT without more advanced, supplementary treatment stages.

Yes. Depending on specific requirements and the level of treatment, the wastewater from NGO’s system can meet standards for reuse for purposes such as irrigating plants on the farm premises or cleaning pens (after additional disinfection measures), helping to save fresh water resources.

Sludge from NGO’s system, especially sludge from the primary settling tank and excess biological sludge, has high organic and nutrient content. We encourage and provide consultation on solutions to process the sludge into high-quality compost fertilizer, promoting resource recycling and reducing waste disposal costs.

See more : https://ngoenvironment.com/en/solution.html

For detailed consultation on livestock wastewater treatment solutions, please contact us at phone number 024.7300.0890 or email office@8ngo.com.

***Please carefully read the Terms of Use – Copyright before copying or quoting the content and images of this website.

This website is the copyright of NGO International Co., Ltd. Any use or reproduction of the content, in part or in whole, in any form, is strictly prohibited, except with explicit written permission from Us.

Tiếng Việt

Tiếng Việt