The Vietnamese coffee industry is facing a dual opportunity and challenge. The opportunity comes from a global market that increasingly favors high-quality, sustainably certified products. The challenge arises from the production process itself—a process that consumes a vast amount of water and generates one of the most “difficult-to-treat” types of wastewater.

I. Roasted Coffee Production and Discharge Reduction Requirements

The coffee production process consumes a large amount of water resources and simultaneously generates a significant amount of wastewater and sludge into the environment.

II.Roasted and Ground Coffee

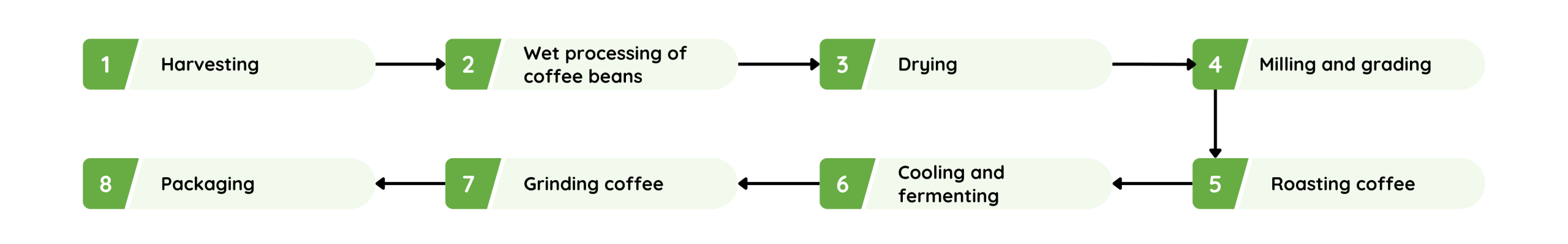

In the production process of roasted and ground coffee, the coffee beans, after harvesting, must undergo processing to remove the fruit’s skin and dry the beans before roasting. There are two main processing methods: wet processing and dry processing.

a. Wet Coffee Processing Method:

The wet coffee processing method is a complex process that requires the use of various machinery and consumes a significant amount of water, commonly applied when processing Arabica coffee.

This method produces coffee beans with a bright, clean flavor profile and is often used for high-quality coffees.

Process and Characteristics of Wastewater Generated from the Wet Method:

| Processing Stage | Task Performed | Wastewater Characteristics |

|---|---|---|

| 1. Harvesting | Coffee is selectively harvested (hand-picking ripe cherries) or strip harvested (picking all cherries, ripe and unripe). |

– Roasted and ground coffee processed using the wet method typically generates a larger volume of water than other methods. – Wastewater from production has a high concentration of pollutants, mainly from the processing of beans through soaking, pulping, fermentation, and washing stages:

– Wastewater from cleaning workshops and equipment:

|

| 2. Wet Processing of Beans | – Step 1: Soaking and sorting cherries – Step 2: Pulping (removing skin and pulp) – Step 3: Fermentation – Step 4: Washing |

|

| 3. Drying | After pulping, the coffee beans must be sun-dried or mechanically dried to reduce the moisture content to about 10-12%. | |

| 4. Hulling and Sorting | – The coffee beans are put into hulling machines to remove the parchment layer, leaving only the green coffee beans. | |

| 5. Roasting | The green coffee beans are put into a roaster at a temperature of about 180-240°C for 8 to 20 minutes (depending on the coffee type and roast profile). | |

| 6. Cooling and Degassing | – Beans can be air-cooled or water-quenched (for certain roasting methods). – After cooling, the coffee needs a degassing period (from 24 to 48 hours) for the flavors to stabilize. |

|

| 7. Grinding | Roasted coffee can be ground into powder (fine, medium, coarse) or left as whole beans depending on the intended use. | |

| 8. Packaging | After being ground or left as whole beans, the roasted coffee is sealed in packages for preservation. |

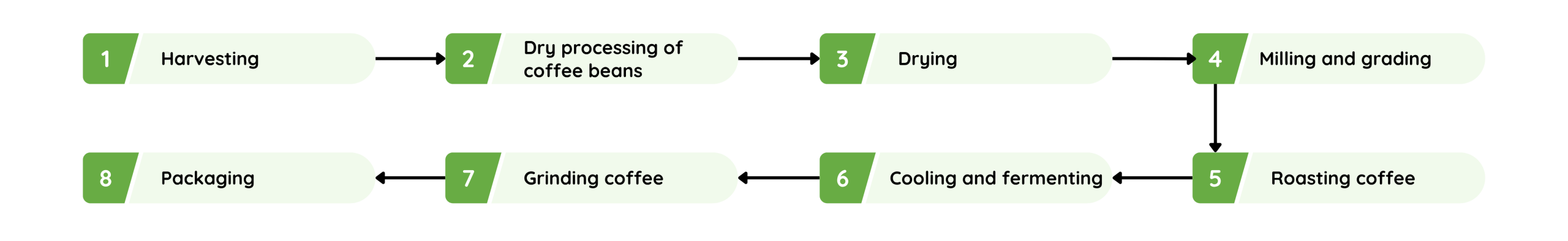

b. Dry Coffee Processing Method:

Dry processing, also known as the natural method, is the more traditional and simpler method. Dry-processed coffee typically has a sweet flavor, heavy body, and strong fruity notes.

In Vietnam, the dry processing method is still the primary and more common method, especially for Robusta coffee, which accounts for the majority of Vietnam’s coffee production (approximately 90% of the output).

Process and Characteristics of Wastewater Generated from the Dry Method:

| Processing Stage | Task Performed | Wastewater Characteristics |

|---|---|---|

| 1. Harvesting | Selective harvesting (hand-picking ripe cherries) or strip harvesting (picking all cherries, ripe and unripe). |

– The dry method typically generates less water than other methods because it primarily relies on the natural drying process without using water in the main processing steps. – Wastewater is mainly generated from cleaning workshops and equipment:

|

| 2. Dry Processing of Beans | – Step 1: Drying the whole cherry – Step 2: Hulling – Step 3: Cleaning and sorting |

|

| 3. Drying | After hulling, the coffee beans must be sun-dried or mechanically dried to reduce the moisture content to about 10-12%. | |

| 4. Hulling and Sorting | – The hulling process removes the parchment layer, leaving only the green coffee beans. | |

| 5. Roasting | – The green coffee beans are put into a roaster at a temperature of about 180-240°C for 8 to 20 minutes (depending on the coffee type and roast profile). | |

| 6. Cooling and Degassing | – Beans can be air-cooled or water-quenched (for certain roasting methods). – After cooling, the coffee needs a degassing period (from 24 to 48 hours) for the flavors to stabilize. |

|

| 7. Grinding | Roasted coffee can be ground into powder (fine, medium, coarse) or left as whole beans depending on the intended use. | |

| 8. Packaging | After being ground or left as whole beans, the roasted coffee is sealed in packages for preservation. |

III. Limitations of Current Wastewater Treatment Solutions for Roasted Coffee Production

Current wastewater treatment methods for roasted coffee production often combine the following treatment processes:

- Mechanical treatment (sedimentation, filtration) to remove suspended solids.

- Physicochemical treatment (coagulation, oil and grease separation) to remove insoluble substances and oils.

- Biological treatment (aerobic, anaerobic) to treat organic substances.

- Membrane filtration technology to improve effluent quality.

Current coffee wastewater treatment methods can handle most pollutant concentrations to meet environmental discharge standards and are applied in many coffee production facilities in Vietnam. However, when considering various factors including treatment efficiency, cost, feasibility, and environmental impact, there are still many limitations:

– Requires a large area to build treatment tanks, which can be a challenge for businesses where land needs to be prioritized for production

– The large volume of wastewater and the monthly discharge fees to industrial parks/clusters represent a significant cost.

– A large amount of sludge is produced that requires subsequent treatment, further increasing disposal costs.

– Biological treatment methods are quite sensitive to fluctuations in pollutant load, causing many factories to face operational difficulties and frequent incidents.

– High electricity consumption, indirectly increasing greenhouse gas emissions

IV. The Solution from NGO International Co., Ltd

We understand that businesses are striving to increase their competitiveness in the market and need to meet the increasingly high demands of Sustainable Development, including standards like Rainforest Alliance, UTZ Certified, and Fair Trade.

NGO has spent years collecting operational data from coffee production plants in Vietnam as well as operational data from coffee wastewater treatment plants to research and develop a solution focused on the goals of energy savings and resource reuse:

V. Frequently Asked Questions

The cost depends on many factors: capacity, processing method (wet/dry), influent quality, and required effluent quality. Please contact us for a detailed and transparent survey and quotation.

We prioritize solutions with a high degree of automation to minimize human intervention. NGO International will provide thorough training and technology transfer to your team until they can operate it proficiently.

Typically, it takes 3-6 months depending on the scale and complexity of the project, including the design, construction, and commissioning phases.

Our solutions focus on sludge minimization and reuse. We will advise on options such as sludge dewatering, drying, and composting to turn sludge into a valuable resource.

Absolutely. Retrofitting old systems to improve efficiency and reduce operating costs is one of our strengths. This is often more cost-effective than building a new one.

Read more : https://ngoenvironment.com/en/solution.html

NGO International Co., Ltd is committed to providing the most advanced, modern technologies to help businesses not only minimize discharge but also enhance production efficiency and protect the environment. Contact us to learn more about our wastewater treatment solutions for roasted coffee production for your business via phone at 024.7300.0890 or email office@8ngo.com for a direct consultation.

***Please carefully read the Terms of Use – Copyright notice before copying or citing the content and images of this website.

This website is copyrighted by NGO International Co., Ltd. Any use or copying of all or part of the content in any form is strictly prohibited, except with explicit written permission from Us.

Tiếng Việt

Tiếng Việt