-

- WATER TREATMENT FOR FOOD & BEVERAGE PRODUCTION MEETING MOH STANDARDS

- PURE WATER PRODUCTION MEETING WHO/ EU/ FDA STANDARDS

- LOW WATER DISCHARGE RATE, SAVING COSTS AND MINIMIZING EFFLUENT.

Food and beverage production activities typically do not require water sources with extremely low electrical conductivity like electronic component or pharmaceutical manufacturing. The required conductivity depends on the specifics of each product. Common water standards for food production are equivalent to QCVN 01:2009/BYT or higher.

I. Water quality standards for food and beverage production

| Parameter | Requirement Description |

|---|---|

| Chemical | – Free from toxic substances, chemical pollutants, heavy metals (Arsenic, Mercury, Lead…)

– Does not exceed permissible Chlorine residuals – pH and hardness are adjusted appropriately so as not to affect product taste and texture |

| Microbiological | – Free from harmful bacteria, viruses, and molds

– Ensures safety and stability for food and beverage products |

| Sediment, suspended solids | – Water is clear, free of mud or suspended particulate matter

– Uses multimedia filters and activated carbon to remove sediment and odors |

| Conductivity / TDS | – Very low electrical conductivity (a few μS/cm or less)

– TDS near zero – Meets ultrapure standards for water used in beverages and functional foods |

Instead of using fixed designs for mass production to cut costs at the expense of quality, we thoroughly assess and review input raw water quality, quality standards required by each factory, and requirements for continuous operation capabilities or self-troubleshooting to design suitable systems for each client.

II. Comprehensive water treatment solutions for the food and beverage industry

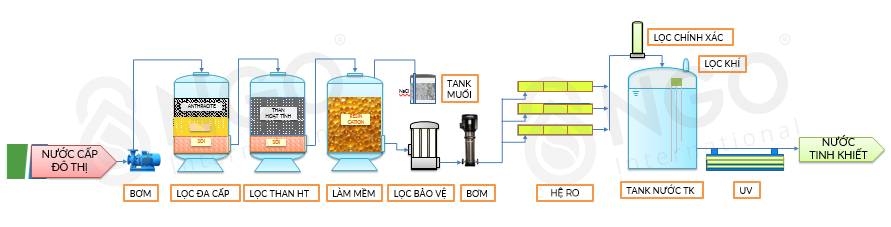

1. Basic pre-treatment in the food and beverage water treatment process

– Removal of most suspended, insoluble solids, helping water achieve necessary clarity

– Adsorption of color, odor, and organic pollutants in water

– Treatment of residual Chlorine in feed water from municipal water supply plants

– Removal of all hardness-causing ions in water, as municipal feed water in Vietnam has very high hardness standards (~ 300 mg/L CaCO3), and most plants currently still supply hard water for domestic use; or factories directly use well water for their production activities.

2. Further treatment of specific pollutants based on each water source

Most water treatment systems at water supply plants in Vietnam lack technological components to treat special pollutants in water sources, such as: Nitrate, Ammonium, heavy metals, high-level organic pollution, to ensure all parameters strictly meet drinking water standards.

Therefore, if the enterprise’s water source is contaminated with these components, constructing the water treatment system requires attention to adding corresponding technological components.

3. Pure water production using RO reverse osmosis system

Some beverage industries such as dairy and beer have higher requirements for the safety and quality of water used in the production process; therefore, many factories will need to equip pure water production systems using **RO reverse osmosis** technology, and typically only 1 RO stage is sufficient.

The function of the RO system is to remove all bacteria, viruses, and water conductivity. After **RO**, all molecules and metal ions with size > 0.001 µm will be removed. However, there is still a risk of bacterial re-contamination in the pipelines or at the point of use.

4. Enhanced sterilization

Disinfection and elimination of bacteria and microbial risks remaining in pipelines using ultraviolet light before use, ensuring 100% pure output water

Pipeline design ensuring high standards to thoroughly eliminate microorganisms not only at the pure filtration system but also at points of use

5. Quality warning & monitoring system

Standards for equipment, pipelines, tools, and installation measures for the water treatment system need to be equivalent to the standards applied by the factory, such as Vietnamese standards or European standards.

Controlling the operation of the pure water production system helps keep quality stable and ensures recommended production standards. Depending on needs, monitoring parameters can be selected, such as quality risk warnings, flow risk warnings, pressure, TOC, conductivity…, as well as the level of automation.

Control is implemented for each device, equipment cluster, and the entire system. Self-washing and self-cleaning modes are activated when warning limits are established.

III. Guide on evaluating & selecting a Pure Water Production System

Do not listen to advertisements; instead, ask specific questions to ensure you are investing in a good system:

- Are design limits clearly stated? No system can handle every input fluctuation without specific calculation limits.

- Is treatment efficiency provided for each treatment step or equipment cluster? No output quality is guaranteed without clarifying the treatment efficiency of each step.

- Are there response protocols for various real-world situations, including incidents?

- Is the system excessively cut back to lower the price, including designing at maximum limits causing equipment lifespan to decline rapidly over time? Are you trading low investment costs for high operating costs?

- Is the system convenient for warranty, maintenance, or periodic replacement?

IV. Frequently Asked Questions

Level 1: Depending on whether water is used indirectly or directly in the product, treated water can be selected to comply with Ministry of Health standards, or meet QCVN 01-1:2024/BYT or QCVN 02:2009/BYT, corresponding conductivity 1000 – 700 EC

Level 2: Pure water standard (1-stage RO) with required conductivity ~ 10 EC

Level 3: Pure water standard (2-stage RO) with required conductivity < 5 EC

Important parameters include: pH, turbidity, total dissolved solids (TDS), microorganisms (E. coli, Coliform), heavy metals, residual chlorine… to ensure water meets QCVN 01:2009/BYT standards or the enterprise’s specific standards.

The system needs to meet food safety standards (HACCP, ISO 22000, GMP), ensure materials in contact with water meet standards, be easy to maintain, operate stably, and continuously control output water quality.

NGO selects equipment & designs that meet the exact and sufficient requirements of each factory, neither cutting back nor over-designing. With NGO, we ensure the design is optimally tailored.

With a global network of partners and Suppliers, NGO possesses a diverse portfolio of equipment and materials and cost advantages when providing solutions for enterprises.

Construction time depends on system scale and complexity, typically ranging from 2 to 3 months, including survey, design, installation, and commissioning.

See more :

https://ngoenvironment.com/en/solution.html

For detailed consultation on feed water treatment solutions for beverage – food production, please contact hotline 024.7300.0890 or email office@8ngo.com.

***Please read the requirements regarding Terms of Use – Copyright carefully before copying or quoting content and images from the website.

This website is the copyright of NGO International Co., Ltd. (NGO International). Any form of use or reproduction of part or all of the content in any form is strictly prohibited, unless with clear written permission from Us.

Tiếng Việt

Tiếng Việt