NGO News – To invest in a qualified wastewater treatment system, businesses need to have a good understanding of the type of wastewater, the nature and capacity of their business as well as have general knowledge about wastewater treatment. The article compiled by NGOs below will help businesses have an overview before investing in wastewater treatment systems.

Step 1: Learn about the origin and nature of wastewater treatment

Wastewater = Water + Pollutants. Wastewater treatment is essentially the reduction or removal of pollutants in the water.

The degree of pollution is expressed in the amount of pollutant components and the concentration of those pollutants in the water. The higher the level of pollution, the more complex the wastewater treatment solution is fundamentally.

Pollutants in water are classified according to the following groups:

- Organic/Inorganic ingredients

- Soluble/insoluble ingredients (suspended in water)

- Nutritional composition, including Nitrogen & Phosphorus

- Fats: animal and vegetable sources or mineral fats

- Heavy metal

- Salt, acid Toxic ingredients such as pesticides

- Garbage of large size

Pollution can also be assessed by lack or disappearance of oxygen in the water.

|

Type of Wastewater |

Treatment standards to be met |

| Domestic wastewater

|

QCVN 14:2008/BTNMT |

| Medical waste water

|

QCVN 28:2010/BTNMT |

| Industrial wastewater

|

QCVN 40:2011/BTNMT

(Some manufacturing industries such as paper, animal husbandry, etc. have their own standards) |

Step 2: Carry out wastewater sampling and testing to determine the pollutant components in the wastewater source and the pollutant concentration of each component (also known as pollution parameters) according to the parameters specified in the relevant QCVN (Vietnam standard)

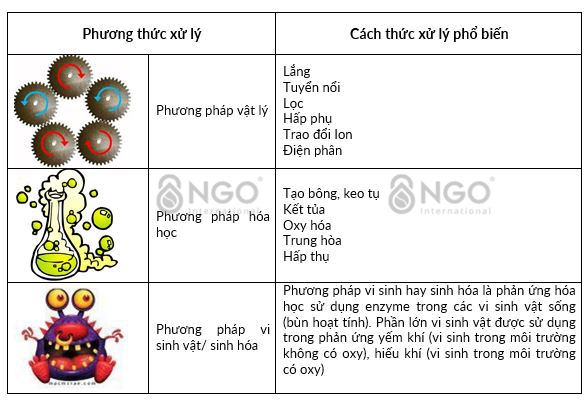

Step 3: Choose a treatment method

Step 4: Select technology

With each method or treatment method, there are many different types of technology and equipment. For example, the physical deposition method can use vertical sedimentation, horizontal sedimentation, laminar sedimentation, and centrifugal sedimentation. The filter method can be selected by material filtration (sand, carbon), filter by precision mechanical equipment, filter by membrane filter, etc.

Depending on the conditions and needs of the business as well as the characteristics of the wastewater to choose the most suitable technology.

Some criteria businesses need to keep in mind when choosing wastewater treatment technology:

Technical criteria

- Wastewater treatment efficiency (compliance with QCVN)

- Treatment efficiency/investment cost

- Lifespan or durability of buildings and equipment

- System building time

Economic criteria

- Cost of construction and installation of equipment (calculated by investment rate): The cost of building a domestic wastewater treatment plant includes the cost of construction materials, labor, transportation, and some other ancillary costs. This cost can be expressed in terms of construction investment per unit of wastewater.

- Cost of operation, maintenance, and repair (calculated in VND/m3 of wastewater): The cost of operating the treatment system includes: cost of electricity, water, chemicals, and labor. Maintenance and repair costs are costs used for maintenance of the system (such as replacement of spare parts and equipment in maintenance, repairs, filter replacement if any).

Environmental criteria

- Rate of use of raw materials and energy

- Reusability of water after treatment

- Degree of sludge and exhaust treatment

- Level of unsafety to the operator, the environment, and solutions to prevent and overcome problems when incidents occur

- Requirements on human resources to manage and operate the wastewater treatment system

Step 5: Popular waste treatment process

A wastewater treatment process usually includes the following treatment steps:

Step 1: Collect wastewater from discharge points (if there are many discharge points)

Step 2: Separating coarse garbage (large particles, large solids)

Step 3: Contain wastewater after collection, stabilize the flow and concentration of pollution in the water tank, also known as the conditioning tank.

Step 4: Primary treatment aka Pre-treatment, e.g. sedimentation/sand, PH neutralization, temperature regulation, grease removal, etc.

Step 5: Microbiological treatment (applied when wastewater has many organic pollutants). Microbiological processes usually include part or all of the following steps: anaerobic microbiological reactions, anaerobic microbiological reactions, and aerobic microbiological reactions.

Step 6: Level 2 sedimentation or filtration to remove residual activated sludge mixed in wastewater after microbiological treatment step.

Step 7: Disinfect to remove pathogenic bacteria

Step 8: Design a tank to store residual sludge generated from the treatment system, including sludge and activated sludge

Step 9: Design the sludge return pipelines

Step 10: Electrical control system

***Vui lòng đọc kỹ yêu cầu về Điều khoản sử dụng – Bản quyền trước khi sao chép hoặc trích dẫn nội dung và hình ảnh của website.

Trang web này thuộc bản quyền của Công ty TNHH Quốc tế NGO (NGO International). Bất kỳ hình thức sử dụng hoặc sao chép một phần hoặc toàn bộ nội dung dưới mọi hình thức đều bị nghiêm cấm, trừ trường hợp được sự cho phép rõ ràng bằng văn bản từ Chúng tôi.

Nguồn: NGO

Tiếng Việt

Tiếng Việt