NGO News – Currently on the market, there are many types of membranes with different designs. The research brings the overview of membranes to customers.

1. Distinguish between water filtration membrane and membrane bioreactor.

• MEMBRANE: is a semi-permeable barrier to separate two streams: water stream and solute stream, the separation is mainly due to pressure.

• Membrane FILTRATION: purely mechanical membrane

• Membrane BIOREACTOR: filtration process combined with biochemical reactions performed by microorganisms, in which microorganisms create a biofilm on the membrane surface.

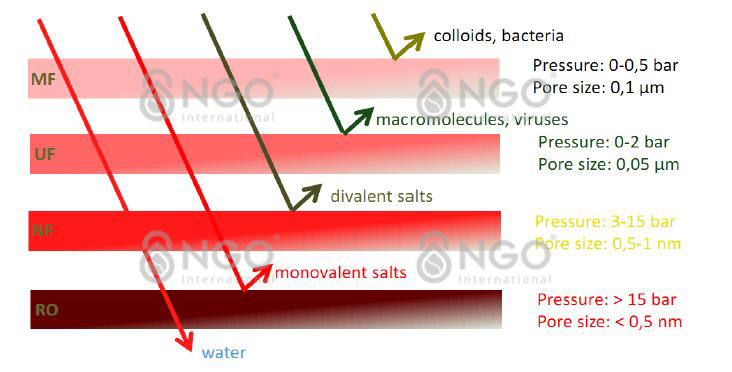

2. Difference between MF (micro filter), UF (ultra filtration), NF (Nano filtration) and RO reverse osmosis membranes

The most basic difference between membrane types is the pore size and the pressure required for clean water to penetrate through the membrane.

Membrane bioreactors are usually MF or UF membranes. Due to the formation of a microbial layer on the membrane surface, the actual membrane pore size for water filtration will be smaller than the manufactured size. When applying the membrane in wastewater treatment, to avoid membrane clogging, the pore size is usually produced in the range of 0.1μm – 0.4 μm.

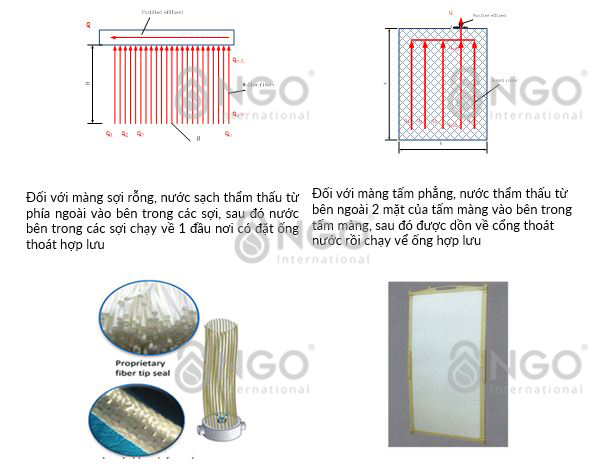

3. Difference between Hollow membrane and Flat sheet membrane

Hollow membranes have tube designs that are fixed at one end or both ends. Flat sheet membranes have a sheet design, commonly with 1 – 2 clean water drainage ports.

Hollow membranes and flat sheet membranes have different flow designs.

For membrane clogging: for hollow membranes, membrane clogging occurs first where the fiber base connects to the water pipe, while for flat sheet membranes, membrane clogging occurs at the point closest to the outlet.

Membrane clogging: occurs due to the accumulation or precipitation of dissolved solids and suspended solids on the membrane surface or inside the membrane. Membrane clogging depends on the following main factors:

- PH

- Lonic strength

- Membrane hydrophobicity

- Membrane charge

- Trans membrane pressure (TMP)

- Cross-flow velocity

- Temperature

- Membrane cleaning mechanism

- Membrane flow structure design

If the membrane clogging is not promptly resolved, irreversible clogging will occur and water production can’t occur.

To prevent membrane clogging and restore membrane flux, membrane manufacturers are currently applying a number of solutions:

- Membrane flow (Continuous process)

- Low transmembrane pressure

- Backwashing (Aeration)

- Cleaning process

Therefore, to evaluate the quality of an MBR membrane, the users need to pay special attention to the following factors:

- Membrane material: durability, acid and alkali resistance, and hydrophilicity of the material

- Pressure across the membrane: pressure to penetrate water through the membrane. The lower the pressure is, the better it is.

- Water filtration capacity per 1m2 of membrane

- Membrane cleaning mechanism by aeration or chemicals

***Vui lòng đọc kỹ yêu cầu về Điều khoản sử dụng – Bản quyền trước khi sao chép hoặc trích dẫn nội dung và hình ảnh của website.

Trang web này thuộc bản quyền của Công ty TNHH Quốc tế NGO (NGO International). Bất kỳ hình thức sử dụng hoặc sao chép một phần hoặc toàn bộ nội dung dưới mọi hình thức đều bị nghiêm cấm, trừ trường hợp được sự cho phép rõ ràng bằng văn bản từ Chúng tôi.

Nguồn: NGO

Tiếng Việt

Tiếng Việt