Internal Circulation (IC) anaerobic treatment is a wastewater treatment technique with many breakthrough advantages. This technology is mainly applied by NGO in treating wastewater rich in organic matter, livestock industry, textile pulp and dyeing and fisheries; food industry wastewater.

1. Overview of internal circulation anaerobic treatment (IC) technique

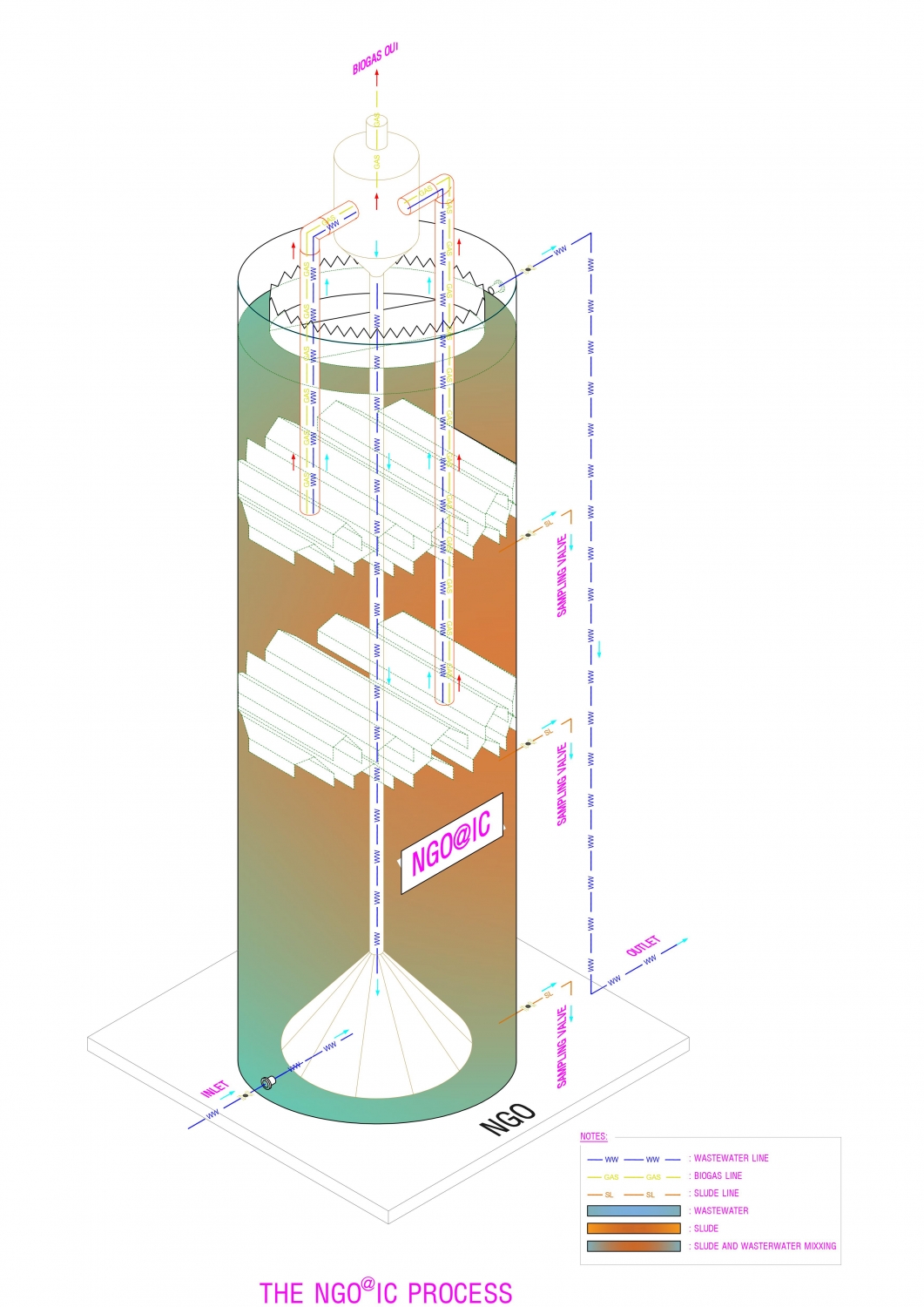

This is an anaerobic microbial pollution treatment technique that includes: input water distribution part, internal circulation structure, lower high load reaction zone and low load reaction zone. The system is based on the principle of two UASB systems stacked on top of each other, in which the high-load UASB system (applying high organic load) is placed at the bottom and the lower-load UASB system is placed on top.

The gas separated from the lower phase separator is collected and moves upward into the gas collection chamber through the rising pipe. When the air flow moves up, it will carry water and sludge from the high-load decomposition zone. After separating the air, water and microorganisms are brought back in through the downpipe. The flow of water and microorganisms back into the high-load reaction zone is a characteristic feature of the IC anaerobic technique.

2. Characteristics of the NGO@IC anaerobic technique

|

● The highlight of this technique is the very high microbial density and internal circulation, so the reverse water flow speed is very high, up to 20 m/h, increasing the mixing ability. The internal circulation flow has a self-regulating nature: high growing media concentration produces a large amount of gas, leading to a large flow rate of the circulation stream, increasing the ability to mix and dilute the input stream. Therefore, the processing capacity of IC is much more efficient than UASB. The IC system has the ability to respond well to fluctuations in growing media concentration in the input stream: the circulating stream contains a lot of bicarbonate, which has a buffering effect, preventing pH reduction in the high-load reaction zone. On the other hand, because the gas has largely been separated in the gas separator No. 1 and the flow rate of the upper zone is low, it creates conditions to retain microorganisms in the reaction mass better than other systems. |

Operating principle of the IC internal circulation anaerobic tank

The tank is usually cylindrical with a height of 19.7m or 23.7m. The diameter ranges from 2.3–10.5 m. The ratio between height and diameter is in the value range of 2.3-8.

The structure of the inflow distributor is cone-shaped. The circulating flow is directed from top to bottom to the cone tip in a tangential direction. They form vortex flows when mixed with the inlet stream.

Above the inflow distribution system is a high-load reaction zone with an expanded layer of microbial particles. Wastewater is fed into the bottom of the treatment system, coming into contact with a high-density granular sludge layer. Here, organic matter decomposition occurs and biogas is formed. The high-load reaction zone extends all the way to the bottom of the first air separator. Thanks to the strong self-stirring ability in the high-load reaction zone, it increases the contact of microorganisms with the substrate. It leads to increased microbial activity efficiency.

The upward flow of air has the effect of carrying part of the water and sludge from the highlands to the gas-liquid-solid separator. There the gas is separated from the liquid and sludge. Sludge and water follow the downward path back to the high-load reaction chamber. After leaving the high-load area, wastewater only contains a small amount of pollutants and flows through air separation system No. 1. This chamber acts as a secondary treatment system and continues the organic matter conversion process. Air separator 2 separates the remaining air.

3. Advantages and limitations of the internal circulation (IC) anaerobic treatment technique

The internal circulation anaerobic treatment technique is essentially an improved UASB system, so it has the same strengths as:

– High COD treatment efficiency.

– Suitable for wastewater with high organic content and large load

– Producing less sludge – reducing sludge treatment costs

– Suitable for recovering biogas and converting it into energy

– Small operating area

If you need advice on solutions, design and construction of the NGO@IC system, please contact the hotline: 0969 867 924 or 0969 867 925

Sources: NGO

Tiếng Việt

Tiếng Việt