Air pollution includes pollutants in solid form (dust), gaseous form (toxic vapors), and liquid form (solvent vapors). Conventional exhaust gas treatment solutions address all three forms of pollution to ensure compliance with current QCVN discharge standards. Greenhouse gas treatment represents a novel approach to air pollution control, aiming for comprehensive treatment of greenhouse gases (e.g., CO₂, CH₄, NOₓ), achieving levels even lower than discharge standards, and striving for zero emissions.

1. Sources of Emissions

- Emissions and hazardous substances that harm human health and ecosystems can originate from industrial production, transportation, daily activities, or natural processes (e.g., organic decomposition).

- Pollutants may include inorganic compounds like ammonia and hydrogen sulfide or organic compounds such as pesticides, organic solvents (methane, butane, benzene, xylene, cyclohexanone, toluene), and volatile organic compounds (VOCs) like those found in food production (spice odors) or cosmetics industries.

2. Solutions for Removing Toxic Gases

2.1. Absorption Method

Principle:

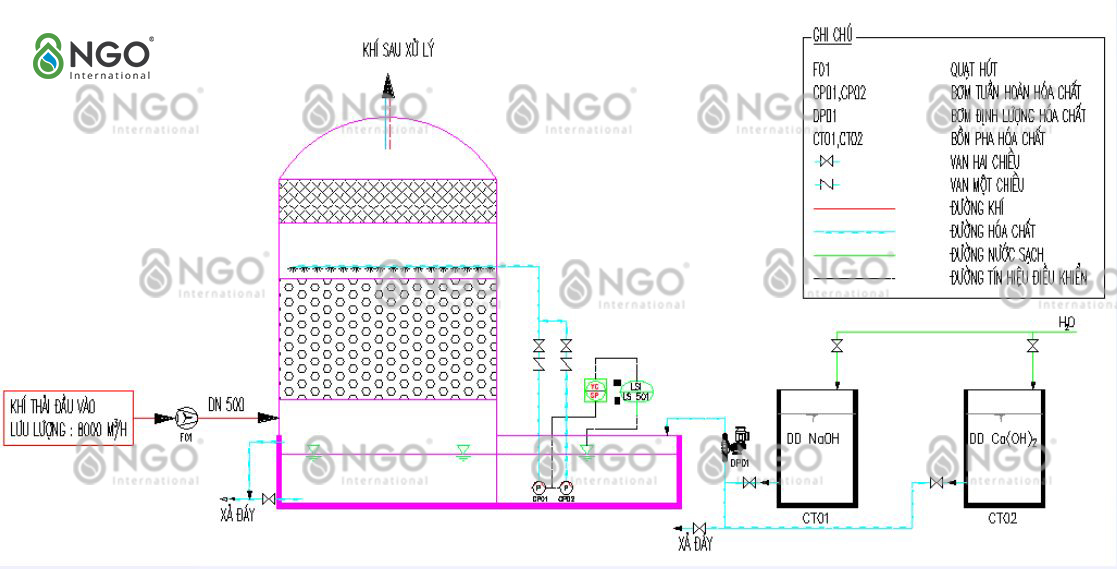

Absorption involves creating contact between a polluted gas stream and small, high-density droplets of an absorbent solution. Pollutants are removed through dissolution in the absorbent liquid or via chemical reactions with the absorbent solution.

Factors affecting efficiency: Surface area of contact between the gas and absorbent droplets, Contact time, Absorbent solution properties, Exhaust gas temperature, Relative motion between gas and solvent streams, Gas flow rate.

Process stages:

- Pollutant molecules diffuse to the absorbent liquid’s surface.

- Gas penetrates and dissolves in the absorbent.

- Dissolved gas diffuses deeper into the absorbent liquid.

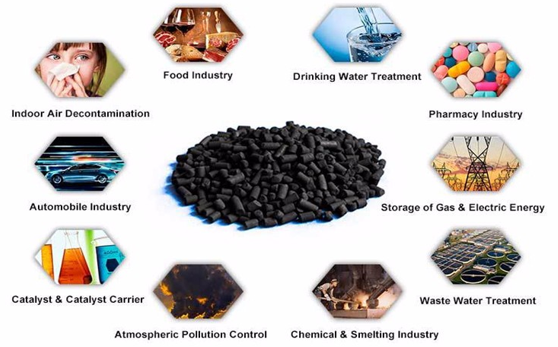

2.2. Adsorption Method

Principle:

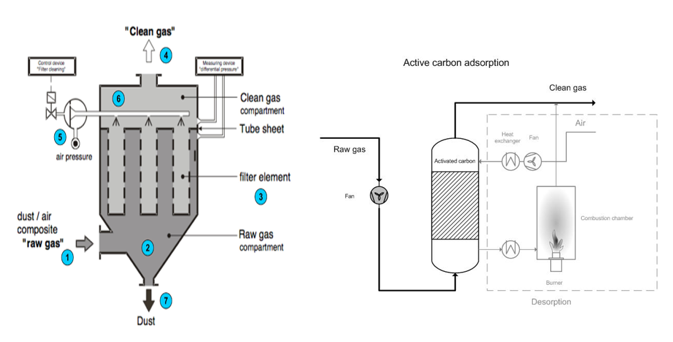

Gas adsorption relies on the ability of solid materials to capture gas molecules. Adsorption occurs when pollutant molecules or atoms concentrate on the surface or within pores of solid adsorbents. Typical adsorbents include activated carbon and silica gel.

Advantages:

- Handles varying flow rates.

- Suitable for different concentrations of organic compounds.

- Reusable or recycled materials (e.g., fly ash) can be employed.

- Simple operation.

- Space-saving.

Applications:

- Exhaust from pharmaceuticals, food and beverage production, wastewater treatment, and chemical industries……

2.3 Oxidation Methods

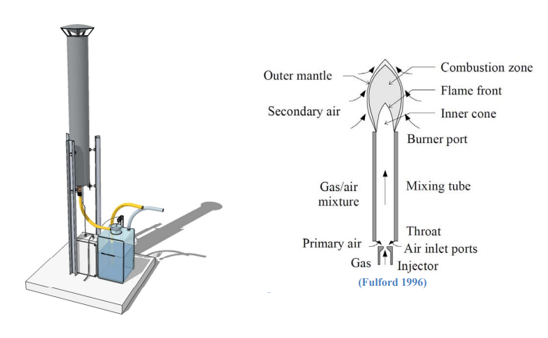

- Thermal Oxidation (Chemical Oxidation):

High temperatures are used to combust or completely oxidize hazardous compounds in the exhaust gas, converting them into safe substances such as CO₂ and H₂O.

Typically, these are refractory organic compounds, often with complex ring structures such as dioxins, furans, and solvent compounds from painting processes. Incineration is the most suitable method for treating these pollutants.

Combustion of pollutants requires additional energy provided by burning fuel. Common fuels used for incinerators include FO oil, DO oil, or gas. The components of solid, liquid, and gaseous fuels generally include C, H, O, S, ash (A), and water vapor (W). Combustion generates dust, CO₂, CO, SO₂, H₂O, and unburned hydrocarbons (HC).

Advantages:

– Thorough removal of organic compounds.

– Suitable for biogas treatment.

- UV Treatment Method

Exhaust gas treatment technology using UV light utilizes ultraviolet light with a short wavelength range from 100 nm to 400 nm, which acts on particles and molecules in exhaust gas. UV rays can break chemical bonds and alter the structure of pollutants, effectively reducing their toxicity or eliminating them. It is applied in treating VOCs, H₂S, NH₃, and odorous gases.

Free negative and positive electrons provided by oxygen combine with oxygen molecules in the air to create ozone, a highly oxidizing compound:

UV + O2 → O– + O * (oxidation reaction) O + O2 → O3 (ozone)

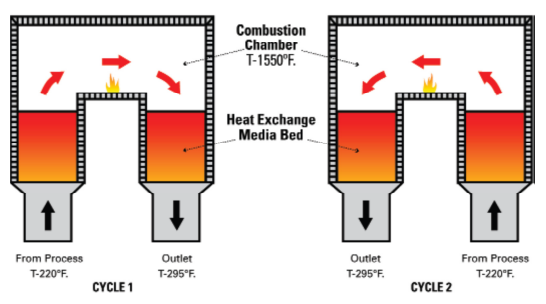

- Regenerative Thermal Oxidation (RTO) / Regenerative Catalytic Oxidation (RCO):

Regenerative Thermal Oxidation (RTO) equipment is widely accepted for controlling volatile organic compounds (VOCs) and hazardous air pollutants (HAPs). RTO can be modified by adding catalysts, commonly referred to as Regenerative Catalytic Oxidation (RCO).

Depending on the characteristics of specific emissions from each facility, evaluating the primary components of the exhaust gas is necessary to select appropriate removal technology or combine multiple processes to meet treatment standards.

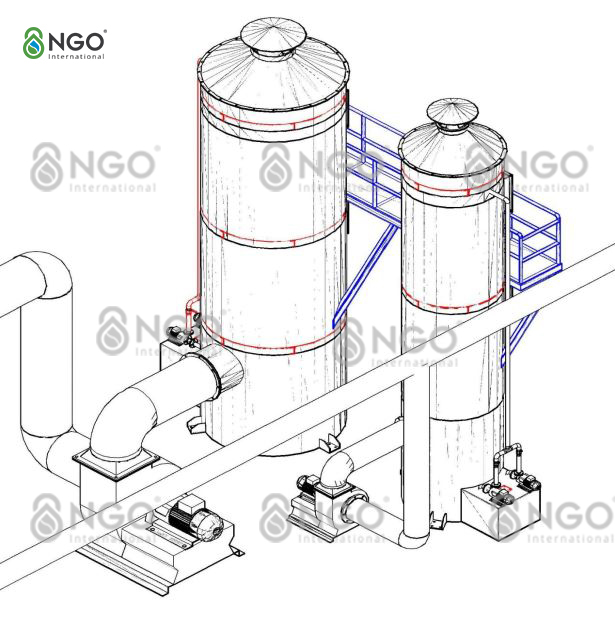

Some Practical Images:

***Please read the Terms of Use – Copyright Policy carefully before copying or quoting content and images from this website.

This website is copyrighted by NGO International Co., Ltd. Any use or reproduction of any part or all content in any form is strictly prohibited unless explicitly permitted in writing by us.

Tiếng Việt

Tiếng Việt