I. General characteristics of pharmaceutical & cosmetic wastewater

Unlike domestic or typical industrial wastewater, pharmaceutical industry wastewater contains complex compounds.

Active Pharmaceutical Ingredients (APIs)

Contains Active Pharmaceutical Ingredients (APIs), excipients, organic solvents (ethanol, methanol…).

Heavy metals

May contain heavy metals from the coating process or equipment.

High pH

pH fluctuates strongly due to the use of acids/bases in production.

Colorants, additives

May contain colorants and additives for pharmaceutical/chemical production lines.

High COD, BOD

High COD and BOD levels, difficult to biodegrade and existing in micro-particle form: Due to containing many organic compounds from drugs, solvents, additives…

Other components

Pollution components change continuously: Because the pharmaceutical industry constantly innovates drug formulas, making control and treatment more difficult.

II. Pharmaceutical wastewater treatment system diagram

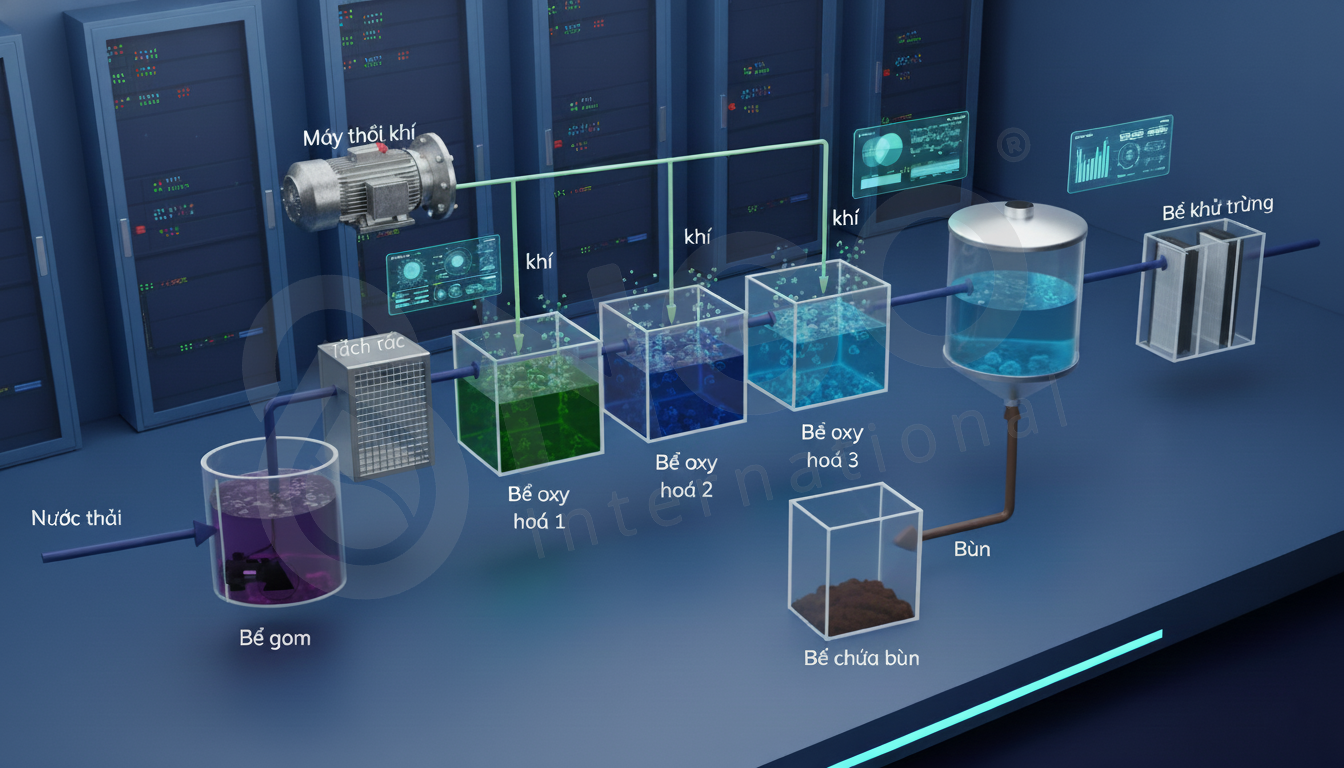

Wastewater from production and cleaning processes is collected in the collection tank, then pumped through the screening device to remove coarse trash, avoiding system clogging. Next, wastewater flows through **serial contact oxidation tanks (1, 2, 3)** – here air blowers provide continuous oxygen for the oxidation process of organic substances (BOD, COD), TN, TP

Contact oxidation filtration technology uses contact materials with a 3D structure submerged in the treatment tank, supplemented with oxygen from air blowers to allow the oxidation reaction of pollution components to take place. Contact materials allow the oxidation efficiency to increase manifold and be distributed evenly throughout all areas of the treatment tank.

R&D results in the lab as well as actual operating data prove COD removal efficiency reaches 125mg/L – 250 mg/L per 1m3 of contact material.

After the reaction stage, pollution components are converted into waste sludge in the water, and separated from the water source at the phase separation tank. Settled sludge and floating sludge are collected in the sludge holding tank for periodic treatment or suctioning. The clear water is sent to the disinfection tank using Chlorine or UV rays to destroy harmful microorganisms before being discharged into the environment, ensuring compliance with discharge regulations.

III. How are Vietnamese Pharmaceutical factories treating wastewater?

Treating production wastewater physically/chemically keeps operating costs high; many factories cannot afford to maintain operation according to the design

For factories using biological technology, microorganisms often encounter load shock phenomena and unstable operation

Operating staff encounter many difficulties in handling incidents during operation, lacking the ability to standardize operating procedures.

IV. NGO’s solution is completely distinct in the market

With understanding of the properties of raw materials used in pharmaceutical and chemical production activities, NGO designs systems with different treatment levels, completely suitable for the specific characteristics of each factory

The system consists of 3 main oxidation reaction treatment steps

Level 1: BOD Oxidation

Level 2: Oxidation of preservatives, surfactants from line cleaning chemicals, and TN nutrients

Level 3: Oxidation of trace soluble COD difficult to biodegrade

NGO’s solution allows:

- Minimizing chemical consumption compared to advanced oxidation or activated carbon adsorption methods

- Stable system operation, good treatment of toxins harmful to microorganisms that cause load shock to the system

- The system personalizes additional treatment steps depending on the reuse purpose of each factory.

VI. Frequently Asked Questions

Absolutely yes. Our system is designed to effectively treat soluble COD components and hard-to-biodegrade COD

Treated water meets discharge standard QCVN 28:2010/BTNMT, column A. If the enterprise has a need, we can integrate higher-level treatment modules for reuse in factory activities

There is no technology “best for all”. The most suitable technology is the one that meets your technical requirements, investment budget, and land fund. NGO International experts will advise on a “tailor-made” solution after actual survey.

The system is designed to minimize manual intervention by operating staff. In addition, Operating staff will be trained by NGO International experts. We are always ready to provide remote or direct technical support when customers need it, so businesses can be assured about the operational aspect

Costs depend on capacity, input pollution levels, and available space at the factory. However, for systems invested to operate in compliance with legal regulations, NGO’s solution commits to lower investment costs and more stable quality compared to advanced oxidation, activated carbon filtration, or other physicochemical solutions on the market.

See more :

https://ngoenvironment.com/en/solution.html

Enterprises interested in Pharmaceutical Wastewater Treatment Solutions, please contact NGO via Hotline 024.7300.0890 or email office@8ngo.com for direct consultation.

***Please read the requirements regarding Terms of Use – Copyright carefully before copying or quoting content and images from the website.

This website is the copyright of NGO International Co., Ltd. (NGO International). Any form of use or reproduction of part or all of the content in any form is strictly prohibited, unless with clear written permission from Us.

Tiếng Việt

Tiếng Việt