WATER TREATMENT FOR FOOD AND BEVERAGE PRODUCTION

- Water is a main input material for beverage, dairy, and food production.

- Water quality has direct impact on the quality of the product and production of eqipment.

- The higher the rate of treated water achieved for the production, the more optimal production cost will be. The lower the removal and discharge ratio, the better

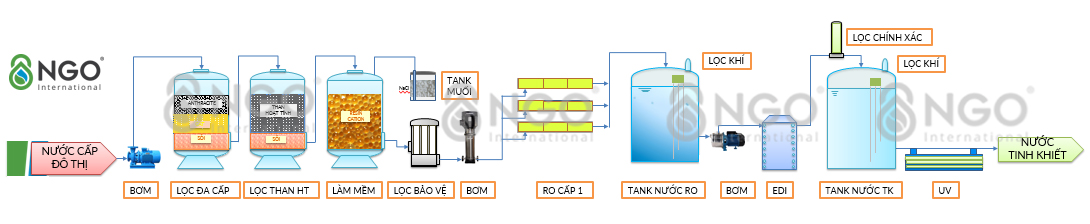

The production of food and beverage usually does not require a water source with a very low conductivity compared to that required by the manufacture of electronic components or pharmaceuticals. The conductivity required will depend on the particularities of the product. Common water standards for food water production are equivalent to QCVN 01: 2009 / BYT or higher.

1. Pretreatment by multi-material filter

- Removal of most of the suspended, pre-insoluble residue, helping to achieve the required transparency

- Adsorption of color, odor, and organic pollutants in water

- Treatment of residual chlorine in water supplied from municipal water plants

2. Water softening

The complete removal of ions that cause hardness in water such as Calcium, Magnesium to eliminate scaling, clogging of pipes, equipment, especially cooling, or boiler systems need special attention, because Vietnam urban water supply is applicable for a high hardness standard (~ 300 mg/L CaCO3), most factories are still supplying hard water for domestic use or directly using well water for their production activities.

3. The further treatment of specific pollutants for each wastewater source

Most water treatment systems in water supply plants in Vietnam do not have technological components to treat special pollution in water source, for example: Nitrate, Ammonium, heavy metals, organic pollution in water sources at high level to ensure all parameters will meet drinking water standards. Therefore, if the enterprise's water source is polluted with these components, it is necessary to pay attention to supplementing the corresponding technological component when building the water treatment system.

4. Purified water production by RO system

Some beverage industries such as the dairy industry and the beer industry have higher requirements on the safety and quality of water used in the production process, so many factories will need to be equipped with purified water production systems with RO technology, and will usually need 1 RO level only.

The function of the RO system is to eliminate all bacteria, viruses, and water conductivity. After RO filtration, all molecules and metal ions larger than 0.001 µm in size will be removed. However, there is still a risk of reinfection of the bacteria on the pipeline or at the point of use.

5. Intensification of sterilization

The sterilization, killing bacteria and risky microorganism on the pipeline by ultraviolet rays before use will ensure 100% pure output water.

High standard pipeline design ensures thorough elimination of microorganisms not only at the filtration system but also at the points of use.

6. Notes on standards

Standards of equipment, pipes, tools and installation methods for water treatment systems should be equivalent to those applied by factories, for example Vietnamese standards or European standards. The system is often designed to be fully automated.

More: Water treatment for food anh beverage production https://www.youtube.com/watch

If your business is interested in solution to inlet water treatment, or has a demand for ion exchange materials, please contact NGO via phone number (024) 3566 8225 or email office@8ngo.com for direct consultation.

thong_tin_lien_quan

-

Wastewater treatment

Wastewater treatment

-

A standard domestic wastewater

A standard domestic wastewater

-

B standard domestic wastewater

B standard domestic wastewater

-

Pig Farm Wastewater

Pig Farm Wastewater

-

Textile dyeing wastewater

Textile dyeing wastewater

-

Paper industry wastewater solution

Paper industry wastewater solution

-

Textile Dyeing Wastewater & Industrial Washing

Textile Dyeing Wastewater & Industrial Washing

-

Slaughter wastewater treatment solution

Slaughter wastewater treatment solution

-

Aquaculture wastewater

Aquaculture wastewater

-

Starch wastewater

Starch wastewater

-

Petroleum wastewater

Petroleum wastewater

-

Beer wastewater

Beer wastewater

-

Other industrial wastewaters

Other industrial wastewaters

-

BioPM - Organic Industrial wastewater treatment solution

BioPM - Organic Industrial wastewater treatment solution

-

MBR solutions

MBR solutions

-

Conventional activated sludge (CAS)

Conventional activated sludge (CAS)

-

Moving bed biofilm reactor (MBBR)

Moving bed biofilm reactor (MBBR)

-

Anaerobic- Anoxic-Aerobic (AAO)

Anaerobic- Anoxic-Aerobic (AAO)

-

Sequencing batch reactor (SBR)

Sequencing batch reactor (SBR)

-

Physical & Chemical methods

Physical & Chemical methods

-

Supply water treatment

Supply water treatment

-

Cooling system water

Cooling system water

-

Water treatment for food and Beverage production

Water treatment for food and Beverage production

-

Ultra pure water supply solution for electronic industry

Ultra pure water supply solution for electronic industry

-

Pure water supply for pharmaceutical manufacturers

Pure water supply for pharmaceutical manufacturers

-

Water Supply treatment with ion exchange method

Water Supply treatment with ion exchange method

-

Ordor Treatment

Ordor Treatment