PETROLEUM WASTEWATER TREATMENT SOLUTION

Oily wastewater is mainly composed of mineral oil, in addition garbage, sediment, clay, surfactants, etc.

Essence of oil is dense liquid, with a featured odor, lighter than water, which is slowly oxidized, can last up to 50 years.

1. Oily wastewater exists in the following status:

- Free-form: This oil will emerge and create oil film. Oil is present in the form of free-oil seeds or mixed with water. Free oil will float on the surface because the specific gravity of oil is lower than the specific gravity of the water.

- Emulsion-form: Formed by chemical agents such as soap, caustic soda, detergents, etc., or asphaltene chemistry altering surface tension and chemically stabilizing the dispersed oils.

- Soluble-form: Soluble molecules.

2. Major sources of oily wastewater include:

- Water uses for periodically cleaning tank at petroleum depots to ensure fuel quality.

- Drain out tank-bottom water after ending the process of ship entering into the storage tank.

- Periodic industrial sanitary water and after finishing amendment of technology, equipment in petroleum depots.

- Rain water falls on the area that can contaminate the oil at the storage and petrol stations.

- Water use for floor cleaning, car wash, car maintenance.

- Cooling water or sewage from mechanical factories

3. Treatment solutions currently applied to petroleum production waste water:

- Coagulation, floatation method: Low cost, easy deployment but not thoroughly treated, because super-small mineral oil molecules are difficult to fully coagulate or flotation. Therefore, after-treatment water normally still contains oil.

- Filtration method by using membrane: Can filter up to 90% of the amount of gasoline in the effluent or higher depending on the filtered material. The cost of treatment is usually very high, the material is not reusable and after-treatment water may still has the characteristic smell of oil.

- Material-adsorption method: Can remove oil thoroughly, but the material is quickly saturated (for example, oil-impregnated cloth), easy to be clogged, especially in waste water with high TSS content, high processing costs

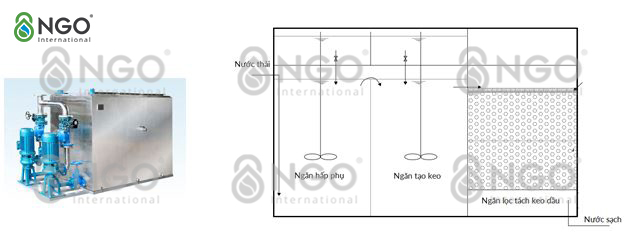

After the study period, NGO could provide a solution Oily wastewater treatment that can thoroughly treat mineral oil by chemical adsorption and has much cheaper cost than using adsorption materials. Reaction time is shorter and mineral oil is removed almost completely. After-treatment water has no odor. The solution is suitable for projects with small scale discharge capacity as well as projects with large discharge capacity.

Wastewater with reside generated from storage tank rinsing process (1-2 year/time) is the effluent source of highest oil contaminated level, from tens to tens of thousands ppm. Characteristics of this type of wastewater is high concentration of oil and high inorganic residue.

If your business is interested in solution to inlet water treatment, or has a demand for ion exchange materials, please contact NGO via phone number (024) 3566 8225 or email office@8ngo.com for direct consultation.

thong_tin_lien_quan

-

Wastewater treatment

Wastewater treatment

-

A standard domestic wastewater

A standard domestic wastewater

-

B standard domestic wastewater

B standard domestic wastewater

-

Pig Farm Wastewater

Pig Farm Wastewater

-

Textile dyeing wastewater

Textile dyeing wastewater

-

Paper industry wastewater solution

Paper industry wastewater solution

-

Textile Dyeing Wastewater & Industrial Washing

Textile Dyeing Wastewater & Industrial Washing

-

Slaughter wastewater treatment solution

Slaughter wastewater treatment solution

-

Aquaculture wastewater

Aquaculture wastewater

-

Starch wastewater

Starch wastewater

-

Petroleum wastewater

Petroleum wastewater

-

Beer wastewater

Beer wastewater

-

Other industrial wastewaters

Other industrial wastewaters

-

BioPM - Organic Industrial wastewater treatment solution

BioPM - Organic Industrial wastewater treatment solution

-

MBR solutions

MBR solutions

-

Conventional activated sludge (CAS)

Conventional activated sludge (CAS)

-

Moving bed biofilm reactor (MBBR)

Moving bed biofilm reactor (MBBR)

-

Anaerobic- Anoxic-Aerobic (AAO)

Anaerobic- Anoxic-Aerobic (AAO)

-

Sequencing batch reactor (SBR)

Sequencing batch reactor (SBR)

-

Physical & Chemical methods

Physical & Chemical methods

-

Supply water treatment

Supply water treatment

-

Cooling system water

Cooling system water

-

Water treatment for food and Beverage production

Water treatment for food and Beverage production

-

Ultra pure water supply solution for electronic industry

Ultra pure water supply solution for electronic industry

-

Pure water supply for pharmaceutical manufacturers

Pure water supply for pharmaceutical manufacturers

-

Water Supply treatment with ion exchange method

Water Supply treatment with ion exchange method

-

Ordor Treatment

Ordor Treatment

_-_NGO__2_jfif_da_sua.jpg)