ULTRA PURE WATER SUPPLY TO ELECTRONIC MANUFACTURERS

1. Standards of water supplied for electronic manufacturing activities

Water supply for electronic manufacturing is often strictly controlled to ensure product quality. Water supply for electronic component manufacturing must be ultra-pure water (UPW), only two components that are oxygen and hydrogen.

At electronics manufacturing plants, ultrapure water for semiconductor manufacturing and ultra pure water supply to electronic manufacturers are often used in the following stages:

• Washing semiconductor components in manufacturing

• Cleaning and other operations, silicon surface oxidation, plating preparation, etc.

• Other applications in the development and manufacture of semiconductor devices, thin film devices, light-emitting diodes, imaging, printing circuits, memory devices, vacuum devices, or electrical devices

Standard for water supply applies to electronic manufacturing operations based on the size of production equipment. Specifically:

|

Parameter |

E1 |

E 1.1 |

E 1.2 |

E2 |

E3 |

E4 |

|

Width of electronic device in manufacturing (micron) |

1,0-0,5 |

0,35 -0,25 |

0,18 -0,09 |

5,0 -1,0 |

>5,0 |

- |

|

Resistor (250C) (online) |

18,1 |

18,2 |

18,2 |

16,5 |

12 |

0,5 |

|

TOC (mg / l) (online for <10 ppb) |

5 |

2 |

1 |

50 |

300 |

1000 |

|

Dissolved oxygen (mg / l) |

25 |

10 |

3 |

- |

- |

- |

|

Residues on tube after evaporation (mg / l) |

11 |

0,5 |

0,1 |

- |

- |

- |

|

Bacteria in CFU / 100 ml |

5 |

3 |

1 |

10 |

50 |

100 |

|

Total silicon (mg / l) |

5 |

3 |

1 |

10 |

50 |

1000 |

|

Dissolved silicon (mg / l) |

3 |

1 |

0,5 |

- |

- |

- |

|

Ammonium |

0,1 |

0,1 |

0,05 |

- |

- |

- |

|

Chloride |

0,1 |

0,05 |

0,02 |

1 |

10 |

1000 |

|

Fluoride |

0,1 |

0,05 |

0,03 |

- |

- |

- |

|

Nitrate |

0,1 |

0,05 |

0,02 |

1 |

5 |

500 |

|

Phosphate |

0,1 |

0,05 |

0,02 |

1 |

5 |

500 |

|

Sulfate |

0,1 |

0,05 |

0,02 |

1 |

5 |

500 |

|

Calcium |

0,05 |

0,02 |

0,002 |

- |

- |

- |

|

Magnesium |

0,05 |

0,02 |

0,002 |

- |

- |

- |

|

Manganese |

0,05 |

0,02 |

0,002 |

- |

- |

- |

|

Nickel |

0,05 |

0,02 |

0,002 |

1 |

2 |

500 |

|

Potassium |

0,05 |

0,02 |

0,005 |

2 |

5 |

500 |

|

Sodium |

0,05 |

0,02 |

0,005 |

1 |

5 |

1000 |

(*) Recommendation for types of water quality are applied as follows:

Type E1: This water is used to manufacture devices with width from 0.5 to 1 mm

Type E 1.1: Used to manufacture devices with a width from 0.25 to 0.35 mm

Type E1.2: Used in the manufacture devices with widths from 0.09 - 0.18 mm. This is the water used for manufacturing of the most important applications

Type E2: Used to manufacture equipment with sizes from 1 -5mm

Type E3: Used to manufacture devices larger than 5mm. This type can be used to manufacture larger components and some small components, which are not affected by small amounts of impurities.

Type E4: Often used for plating solutions and for other applications that use lower water quality

2. Water supply for electronic manufacturing activities:

Currently in Vietnam, there are two main sources of water for electronic manufacturing, namely undergroundwater or water from clean water supply plants in the area.

However, the quality of underground water is currently not guaranteed and may have possibility of pollution, containing heavy metals, microorganisms ... due to domestic and production activities. Therefore, electronic manufacturers are required to treat input water.

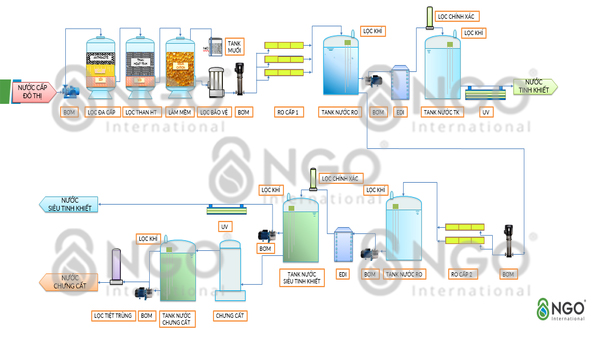

3. Solutions to treatment of electronic water supply provided by NGO:

Technological advantages:

- Water can be extracted from different treatment points to serve each stage of use in the production line, the final treatment water is ultra-pure water and meets today's strictest requirements for quality

- Equipment imported from reputable firms in the world has been certified for quality

- The concentrated water from the filtration system can be reused

- Low power operation, only ~ 0.06 ~ 0.12 KWH / m3.

- Can be integrated with the waste treatment system to build a ZERO-DISCHARGE solution (no discharge)

- Online control system strictly controls all the operating parameters of the system

- Multinational and experienced technology consultant team

- Dedicated technical support and maintenance service.

If your business is interested in solution to inlet water treatment, or has a demand for ion exchange materials, please contact NGO via phone number (024) 3566 8225 or email office@8ngo.com for direct consultation.

thong_tin_lien_quan

-

Wastewater treatment

Wastewater treatment

-

A standard domestic wastewater

A standard domestic wastewater

-

B standard domestic wastewater

B standard domestic wastewater

-

Pig Farm Wastewater

Pig Farm Wastewater

-

Textile dyeing wastewater

Textile dyeing wastewater

-

Paper industry wastewater solution

Paper industry wastewater solution

-

Textile Dyeing Wastewater & Industrial Washing

Textile Dyeing Wastewater & Industrial Washing

-

Slaughter wastewater treatment solution

Slaughter wastewater treatment solution

-

Aquaculture wastewater

Aquaculture wastewater

-

Starch wastewater

Starch wastewater

-

Petroleum wastewater

Petroleum wastewater

-

Beer wastewater

Beer wastewater

-

Other industrial wastewaters

Other industrial wastewaters

-

BioPM - Organic Industrial wastewater treatment solution

BioPM - Organic Industrial wastewater treatment solution

-

MBR solutions

MBR solutions

-

Conventional activated sludge (CAS)

Conventional activated sludge (CAS)

-

Moving bed biofilm reactor (MBBR)

Moving bed biofilm reactor (MBBR)

-

Anaerobic- Anoxic-Aerobic (AAO)

Anaerobic- Anoxic-Aerobic (AAO)

-

Sequencing batch reactor (SBR)

Sequencing batch reactor (SBR)

-

Physical & Chemical methods

Physical & Chemical methods

-

Supply water treatment

Supply water treatment

-

Cooling system water

Cooling system water

-

Water treatment for food and Beverage production

Water treatment for food and Beverage production

-

Ultra pure water supply solution for electronic industry

Ultra pure water supply solution for electronic industry

-

Pure water supply for pharmaceutical manufacturers

Pure water supply for pharmaceutical manufacturers

-

Water Supply treatment with ion exchange method

Water Supply treatment with ion exchange method

-

Ordor Treatment

Ordor Treatment

_-_NGO__2_jfif_da_sua.jpg)