BioPM - EXCELLENT SOLUTION FOR ORGANIC INDUSTRIAL WASTEWATER TREATMENT

BioPM (Biofilter for production & manufacturing) is a solution for organic industrial wastewater treatment by filtration method through biofilms, which has outstanding performance compared to traditional activated sludge solution and brings the high efficient filtration. Water after treatment can meet standard A and can be reused for non-drinking purposes. BioPM solution doesn’t require strict control of viscosity, microbiological density, sludge reflux or sedimentation, therefore it helps reduce many responsibilities and tasks for the operational staff.

BioPM is particularly effective when applied to processing and manufacturing enterprises whose wastewater has a high organic matter content (usually BOD / COD ≥0.2), for example:

- Food processing and seafood processing enterprises

- Beverage manufacturing enterprises

- Coffee production enterprises

- Industrial parks and enterprises have high numbers of employees

- Urban domestic wastewater treatment system

- …..

Outstanding advatanges and values that BioPM brings to customers:

- Reduce construction cost up to 50%

- Low sludge treatment cost, Reduce operational cost

- Low energy consumption

- Thorough treatment of total nitrogen due to anoxic biofilms formed in the filtered layer

- Withstand up to 20% -30% input fluctuations of capacity or concentration

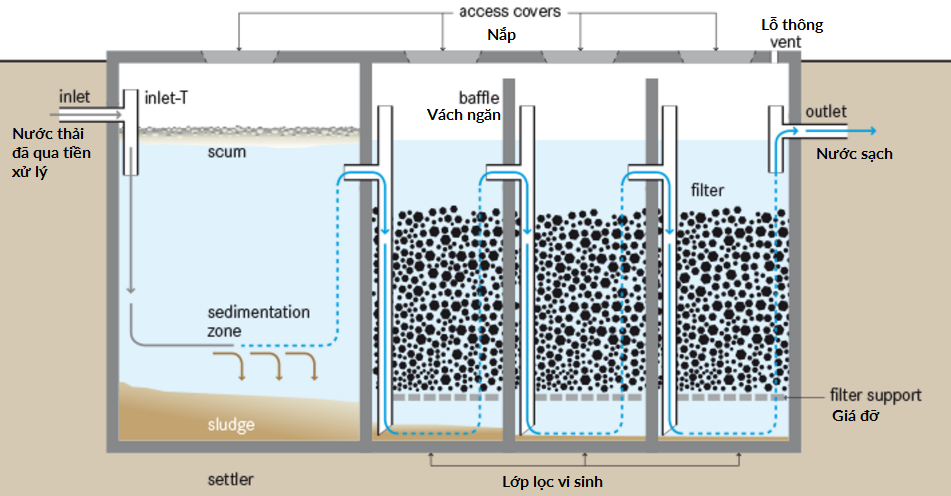

How does BioPM works?

- BioPM treats pollutants through microbial filtration tanks, including partial or completed filtration steps: anaerobic, anoxic or aerobic filtration. Water flow is designed in the upward direction. After passing through these filters, organic pollutants and nutrients are thoroughly treated to meet A standard - QCVN40: 2011/ BTNMT.

- Because of using filtration mechanism, the treatment system does not require a sludge sedimentation tank before discharging into the environment. Sludge is maintained in filtered layers instead of suspended in wastewater, therefore water quality is guaranteed and the operational process will be simpler than traditional activated sludge technology

- The difference in the application of BioPM for different manufacturing wastewater is pre-treatment (primary treatment), depending on the specific characteristics of the wastewater.

Volume for BioPM System

- The volume will be optimized based on: (i) Capacity, (ii) continuous or periodic discharge features, (iii) pre-treatment steps depending on the characteristics of the water, (iv) COD concentration in wastewater and (v) actual footprint of customer

- In order to save footprint, the microbial filtration layers can be designed to increase the micro-density, therefore the amount of pollutant that can be treated per 1 m2 of tank is increased.

-

Wastewater treatment

Wastewater treatment

-

A standard domestic wastewater

A standard domestic wastewater

-

B standard domestic wastewater

B standard domestic wastewater

-

Pig Farm Wastewater

Pig Farm Wastewater

-

Textile dyeing wastewater

Textile dyeing wastewater

-

Paper industry wastewater solution

Paper industry wastewater solution

-

Textile Dyeing Wastewater & Industrial Washing

Textile Dyeing Wastewater & Industrial Washing

-

Slaughter wastewater treatment solution

Slaughter wastewater treatment solution

-

Aquaculture wastewater

Aquaculture wastewater

-

Starch wastewater

Starch wastewater

-

Petroleum wastewater

Petroleum wastewater

-

Beer wastewater

Beer wastewater

-

Other industrial wastewaters

Other industrial wastewaters

-

BioPM - Organic Industrial wastewater treatment solution

BioPM - Organic Industrial wastewater treatment solution

-

MBR solutions

MBR solutions

-

Conventional activated sludge (CAS)

Conventional activated sludge (CAS)

-

Moving bed biofilm reactor (MBBR)

Moving bed biofilm reactor (MBBR)

-

Anaerobic- Anoxic-Aerobic (AAO)

Anaerobic- Anoxic-Aerobic (AAO)

-

Sequencing batch reactor (SBR)

Sequencing batch reactor (SBR)

-

Physical & Chemical methods

Physical & Chemical methods

-

Supply water treatment

Supply water treatment

-

Cooling system water

Cooling system water

-

Water treatment for food and Beverage production

Water treatment for food and Beverage production

-

Ultra pure water supply solution for electronic industry

Ultra pure water supply solution for electronic industry

-

Pure water supply for pharmaceutical manufacturers

Pure water supply for pharmaceutical manufacturers

-

Water Supply treatment with ion exchange method

Water Supply treatment with ion exchange method

-

Ordor Treatment

Ordor Treatment