PFCo - A new flocculant for supply water treatment

1. What is PFCo?

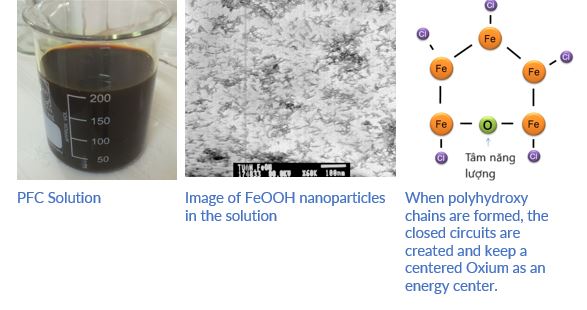

- PFCo polyferrichloride is a long chain polymerized inorganic compound, which is in the form of a brownish-yellow liquid. PFCo has general chemical formula of [Fen(OH)mClx] with n is up to 2,000 – 4,000.

- PFCo is the cost-effective solution to solve many headache problems in supply water and wastewater such as TSS or turbidity, partial COD removal, heavy metals i.e. arsenic, lead... etc, color removal, phosphorus removal, better sedimentation time, reduced surplus sludge generation,…

- PFCo is superior to almost all common flocculants available in the market, such as aluminum alumina (Al2(SO4)3.18H2O), alum iron (Fe2(SO4)3.nH2O, PAC ([Al2(OH)nCl6.nxH2O] m) or discolorants.

2. Outstanding advantages of PFCo in supply water treatment

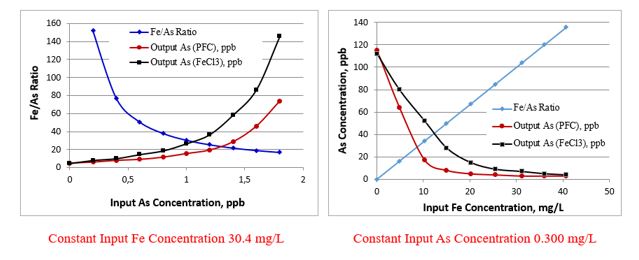

2.1. Remove Arsenic in groundwater down to WTO standards (10 ppb)

- In actual applications, when arsenic concentration in groundwater is 0.1mg/L and Fe> 5mg/L, after treatment with PFCo, the concentration of arsenic decreases to 0.01mg/L, ~ 10 ppb. Arsenic concentration that PFCo can thoroughly treat in groundwater is up to 300 ppb.

2.2. Removal efficiency is upto 99% TSS and 80% COD

- With a long polymerized chain, PFCo has ability to remove suspended solids efficiently and thoroughly. The higher the turbidity level is, the better efficiency PFCo achieves. Particularly, PFCo can absorb and remove up to 80% COD in water in case surface water or groundwater has high COD content (due to dead water zones, seasonal factors, or high polluted water sources).

- We have conducted experiments to determine the effect of PFCo dosage on COD removal efficiency with some water samples and realize that when the dosage is increasing higher (above 0.45 mg/L with 1.5% concentration), the COD removal efficiency will decrease because of the reverse dissolving process of colloidal particles in water.

2.3. Heavy metals Removal

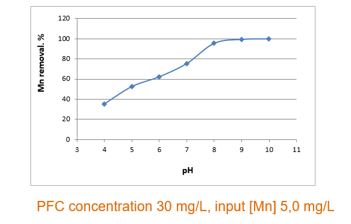

- PFCo can remove up to 80% Manganese (Mn) in water at neutral PH. When pH >7, Mn removal efficiency increases to ~100% due to Mn2+ is oxidized and forms MnO2 that is insoluble in water and can be settle down with iron hydroxide.

- Similar to other heavy metals in water as lead, magnesium, mercury…, PFCo also has a good flocculation capability. Water after treatment with PFCo doesn’t contain excess aluminum, chlorine or heavy metal, other harmful substances and has no conversion of iron ions in water.

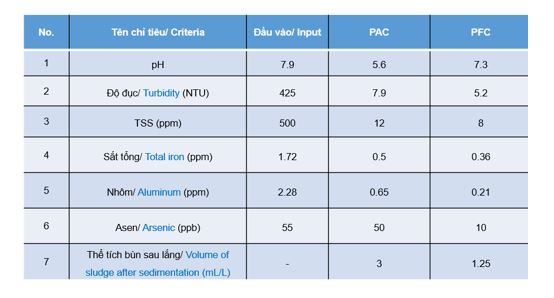

- For example, with a same water sample, using PAC and PFCo to treat water with the same dosage (150g/L, 0.3 ml/L), the excess aluminum, and iron in water after treatment with PFCo are very low. Details in the table below:

2.4. Sedimentation speed and Surplus sludge volume

- PFCo is completely soluble in water. After injecting and mixing PFCo into water, PFC immediately separates the impurities from the water in 1ms. PFCo has quick coagulation and settling process. The produced surplus sludge volume is only one third compared to other coagulants.

2.5. Other advantages

- No impact on PH of water after treatment: PFCo after hydrolysis produces hydroxide and only produces one H+ in water, therefore PH level of water after treatment will be kept in quite stable status and cause less equipment corrosion.

- No need to adjust PH before reaction: PFCo can react in wide pH range, from 4 to 11. The optimal reaction will be at pH level from 6-9, nearly no need to use pH regulators like NaOH or other chemicals to adjust pH of wastewater when using PFCo.

- Reduce the operating cost of filtration system: Because of the efficient adsorption of COD in water and the production of smaller sludge volume, PFCo can help reduce the operating cost of materials in the filtration stage at water treatment factories, including: reduce the consumption of activated carbon material, less backwashing frequency & longer service life of quartz sand filtration.

- No residue: PFCo doesn’t produce residues and helps protect pipelines and equipment better.

- Reduce COD, BOD in supply water and don’t need to add microbiological treatment system

3. How to use PFCo for supply water plants?

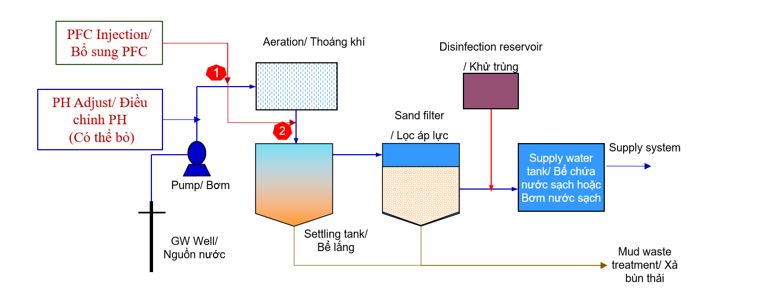

- When using PFCo to treat water supply, water treatment plants do not have to change their systems or add new treatment steps, apart from the need of adding PFCo tank. PFCo can be poured by a dosing pump into the mixing tank, which can be put in either of two positions: (1) before the aeration tank, or (2) before the sedimentation tank as illustrated in below diagram

4. PFCo common dosage for supply water treatment

- Depending on the pollution concentration of water treatment, the dosages of PFCo are different. According to our actual application and experiment, the commonly used dosage for normal supply water treatment is 0.05 – 0.3L 15% per 1m3 water.

5. PFCo Transportation to factories

6. Successful case studies

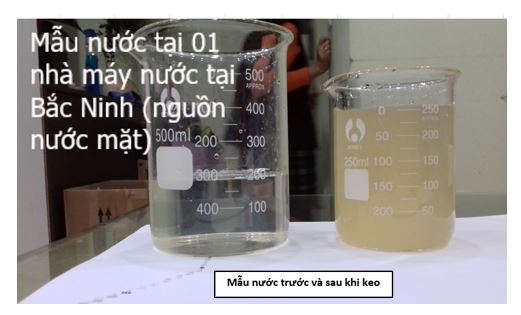

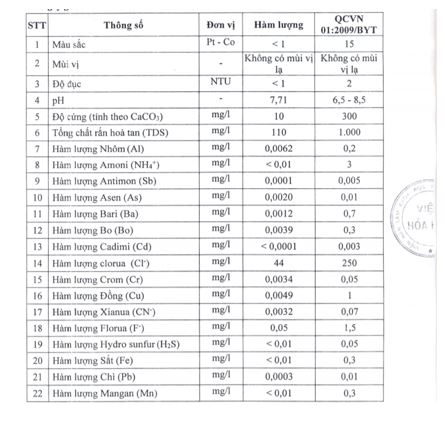

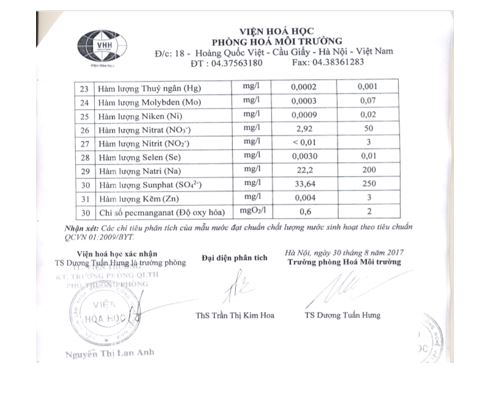

- PFCo has been successfully applied in many supply water factories. Water after treatment meets QCVN 01:2009/BYT, refer to the test results as below:

For more information about the product, please contact via phone number (+84) 1664 184 216 or email office@8ngo.com!

Source: NGO