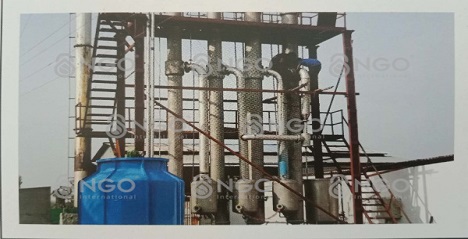

ELECTRO IONIZATION EQUIPMENT

Code: Electroionizationforsaltrecovery Giá: 0 vnđElectro Ionization Equipment is a modern technology, capable of effective salt recovery while minimizing hardness as well as TDS concentration in water, especially suitable for textile dyeing industry.

1. Advantages of Electro Ionization Equipment:

- 98% pure NaCl solution recovered from wastewater

- Hardness less than 10 mg/L. Achieving TDS values below 2100 mg/L according to pollution control criteria

- Faster reproducibility of dyeing due to homogenous saline solution

2. Working process of Electro Ionization Equipment:

- During reactive dyeing, salts such as Sodium Chloride (NaCl) are placed in the dyeing chamber to aid in the reduction of various dye chemicals onto fabrics, while bases are added to increase the pH from neutral level to pH 11 for good dyeing quality. The used dye solutions are then discarded with previously added salts and bases as well as unspecified dyes. As a result, many raw materials are lost along with the waste stream to the environment. Whereas if other contaminants are treated with different techniques, salts will remain in the outlet water, resulting in high TDS concentrations. Therefore, the NaCl salt can be recovered for reuse in the dyeing process by using a nanofiltration membrane system.

- Electrolytic oxidation reactions:

NaCl --> Anode --> Na+ + Cl- + e-

2H2O+e- --> Cathode --> H2 + 2OH-

Na+ + Cl- + 2OH --> NaOCl + H2O

Cl- + Cl- --> Cl2

- Residual chlorine is removed by automatic dosing SMBS after electrolytic oxidation and before the membrane:

NaOCl + NaHSO3 --> Na2SO4 + HCl + NaCl

Cl2 + 4NaHSO3 --> 2NaCl + Na2SO4 + 2H2O + 3SO2

If your business is interested in solution to inlet water treatment, or has a demand for ion exchange materials, please contact NGO via phone number (024) 3566 8225 or email office@8ngo.com for direct consultation.

Similar Product

.jpg)